How to Make Pipe Lagging Waterproof: A Guide for Outdoor and Underground Pipes

Protecting your pipes from water damage is crucial, especially for outdoor or underground systems exposed to rain, condensation, or soil moisture. At Pipelagging.com, we offer a range of products to help you create a waterproof lagging solution that’s durable and easy to install. Whether insulating HVAC, refrigeration, or mains water pipes, this guide will walk you through the steps to keep your pipes dry and efficient. Perfect for DIY enthusiasts and professionals alike, these tips will save you time and money while extending the life of your pipework.

Why Waterproof Pipe Lagging Matters

Water exposure can degrade pipe lagging, reduce thermal efficiency, and cause corrosion or freezing in pipes. Waterproof lagging prevents:

- Moisture ingress that leads to mould or material breakdown.

- Condensation on cold water pipes can cause corrosion.

- UV damage to outdoor pipes exposed to sunlight.

- Mechanical damage from wildlife or environmental stress.

By choosing the right materials and sealing techniques, you can ensure your pipes stay protected in harsh conditions. Let’s dive into how to achieve this using products available at Pipelagging.com.

Step-by-Step Guide to Waterproof Pipe Lagging

1. Select Waterproof Lagging Materials

Start with materials designed for water resistance, available directly from our store:

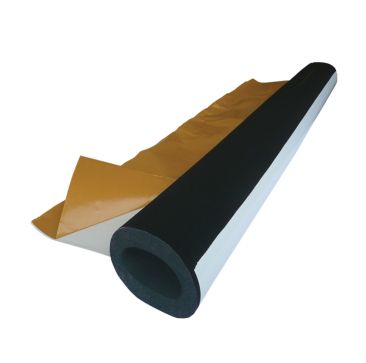

- Armaflex Tuffcoat Pipe Lagging: This nitrile rubber foam comes with a pre-applied tough PVC coating, making it waterproof, UV-resistant, and ideal for outdoor or underground use. It’s perfect for HVAC, refrigeration, and mains water pipes, available in 1m lengths with thicknesses of 13mm, 19mm, or 25mm for pipe sizes from 10mm to 89mm. The built-in adhesive lap ensures a watertight seal during installation. Shop Armaflex Tuffcoat now.

- Armaflex HT EPDM Lagging: Made from EPDM rubber, this weatherproof and UV-resistant option is designed for high-temperature pipes (up to 150°C), such as solar or external pipework. It requires no extra covering, offering a low-maintenance waterproof solution. Opt for a minimum 19mm wall thickness to protect against freezing. Explore Armaflex HT EPDM.

- Polyisobutylene (PIB) Sheeting: For an additional waterproof layer, PIB sheeting is completely impervious to water and durable across a wide temperature range (-30°C to 100°C). It’s easy to install by brushing overlaps with PIB solvent to create a welded, watertight seal. This is a go-to choice for harsh environments like chemical plants or coastal areas. Find PIB Sheeting here.

Pro Tip: For outdoor pipes, prioritise Tuffcoat or HT EPDM to withstand UV rays and rain. For underground applications, Tuffcoat’s corrosion resistance makes it a top pick.

2. Seal Joints and Seams for Maximum Protection

Proper sealing is critical to prevent water from seeping into gaps. Use these products from Pipelagging.com:

- Armaflex 520 Adhesive: Designed for nitrile rubber products like Tuffcoat, this adhesive creates a strong, watertight bond for slit lagging or joints. Apply it evenly to ensure no moisture can penetrate.

- Armaflex 625 Adhesive: Pair this with Armaflex HT EPDM for UV-resistant, high-temperature applications. It maintains the lagging’s waterproof integrity.

- Armacell Adhesive Tapes: These tapes are tailored for Armaflex products. They seal seams and joints to block water ingress. They’re easy to apply and ensure a professional finish.

- Waterproof Mastic or Tape: For added protection, apply waterproof mastic or tape over joints, especially bends or T-joints, to create a seamless barrier.

Installation Tip: For bends, cut lagging at a 45-degree angle using a mitre box for a snug fit, then seal with adhesive or tape. For stopcocks, wrap carefully and secure with tape to eliminate gaps.

3. Protect Standard Lagging with Waterproof Layers

If you’re using non-waterproof lagging, such as standard nitrile foam or polyethylene from our range, enhance its water resistance:

- PVC Jacketing: Wrap the lagging in a PVC jacket to shield it from moisture and UV exposure. This is a cost-effective way to upgrade standard materials for outdoor use.

- Aluminium Cladding: For heavy-duty protection, apply aluminium cladding to deflect water and resist mechanical damage.

- Vapour Barrier Films: These films add an extra layer to prevent moisture penetration, ideal for cold water pipes prone to condensation.

- PIB Sheeting: As mentioned, PIB sheeting can wrap any lagging for complete waterproofing. Its solvent-welded seams make it a reliable choice for long-term protection.

For underground pipes, place standard lagging in protective plastic ducting before burial to prevent soil pressure damage and enhance waterproofing.

4. Best Practices for Installation

To ensure your lagging stays waterproof, follow these guidelines:

- Measure Precisely: Match the lagging to your pipe diameter (e.g., 10mm to 89mm for Tuffcoat) to avoid gaps where water could enter. Use our sizing guides at Pipelagging.com.

- Seal Thoroughly: Double-check all joints and seams for complete adhesive or tape coverage. Even small gaps can compromise waterproofing.

- Ventilate During Installation: When using adhesives, work in a well-ventilated area and wear gloves to handle nitrile or EPDM materials safely.

- Inspect Regularly: Check your lagging annually for wear, especially in harsh environments. Reseal or replace damaged sections promptly.

- Consult Professionals for Complex Jobs: For large-scale or underground projects, consider hiring a professional to ensure compliance with building regulations.

5. Tailoring Solutions to Your Needs

- Outdoor Pipes: Armaflex Tuffcoat or HT EPDM are the best choices for resisting rain, UV rays, and wildlife (Tuffcoat for birds or rodents). Their built-in protections reduce maintenance.

- Underground Pipes: Tuffcoat’s PVC coating and corrosion resistance make it ideal. Pair with PIB sheeting for extra security in wet soil.

- Condensation-Prone Pipes: Closed-cell foams like Tuffcoat prevent moisture buildup on cold water pipes, reducing corrosion risks.

Why Choose Pipelagging.com?

At Pipelagging.com, we stock a comprehensive range of waterproof lagging solutions, from Armaflex Tuffcoat to PIB sheeting, all backed by fast UK delivery and expert support. Our products meet high industry standards, ensuring reliable performance in domestic and commercial projects. Need help choosing the right product? Call us at 0161 775 1190 or browse our full range online.

References and Further Reading

For more information on pipe lagging and waterproofing, check these trusted resources:

- Armacell Technical Guides: Armacell, the maker of Armaflex, provides detailed installation advice for waterproof lagging. Visit www.armacell.com for technical data sheets.

- BSI Standards for Insulation: The British Standards Institution outlines requirements for pipe insulation, including waterproofing for outdoor use. Search for BS 5422 on www.bsigroup.com.

- CIBSE Guides: The Chartered Institution of Building Services Engineers offers insights on pipe insulation for energy efficiency and moisture control. Explore their resources at www.cibse.org.

- Energy Saving Trust: Learn about reducing heat loss with proper lagging, including waterproof solutions, at www.energysavingtrust.org.uk.